The Single Strategy To Use For Custom Plastic Machining & Fabrication Services

Unknown Facts About Plastic CNC Machining Services - Ardel Engineering

Drawbacks, Pure polycarbonate does not have great wear resistance and is susceptible to scratches. Anti-scratch coverings and vapor polishing can be included as a post processing action to improve wear resistance or optical clearness, if required. It is also not readily available in pieces over 2 inches thick, which restricts the size of parts that can be made of polycarbonate.

Main Takeaways, Hopefully, this guide has actually provided insight into which plastic is finest fit to your application. To find out more on additional CNC materials and CNC machining services in general, go to Fictiv's website.

1,423 Cnc Plastic Photos - Free & Royalty-Free Stock Photos from Dreamstime

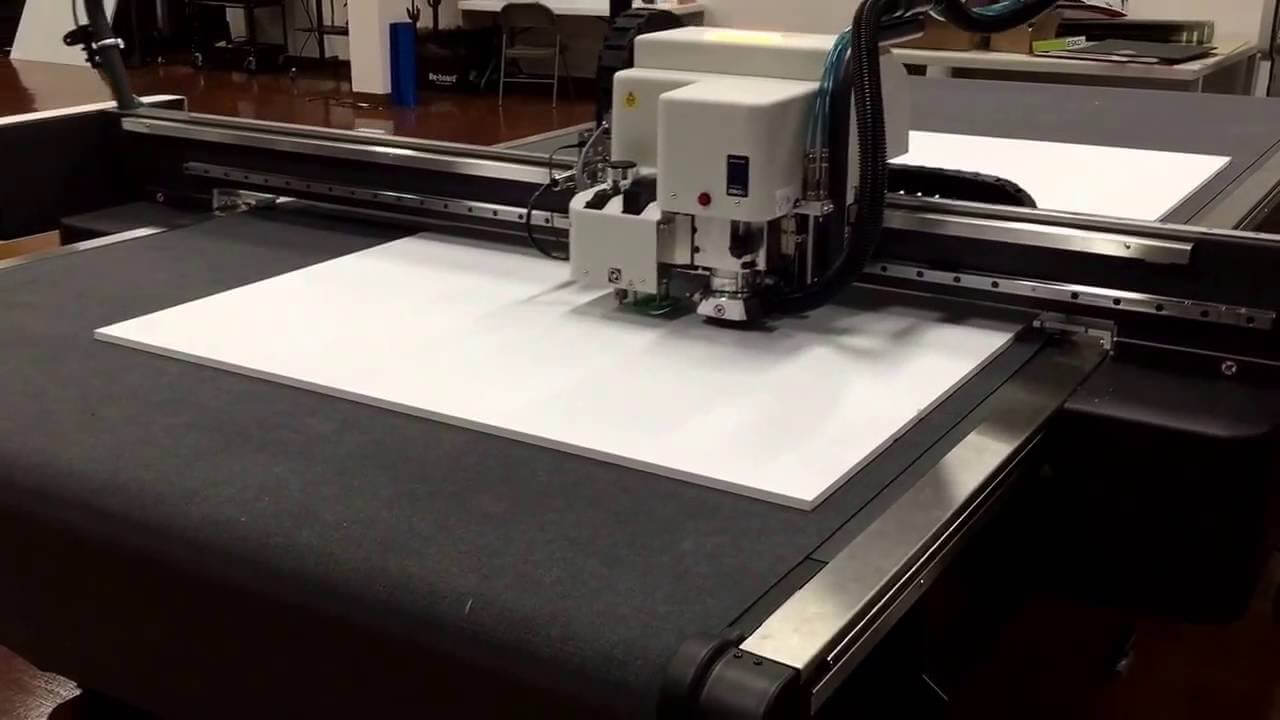

5-Axis cnc router for Plastic /Wood/ Foam /PE/Heavy Duty Industrial /multi-axis - eBay

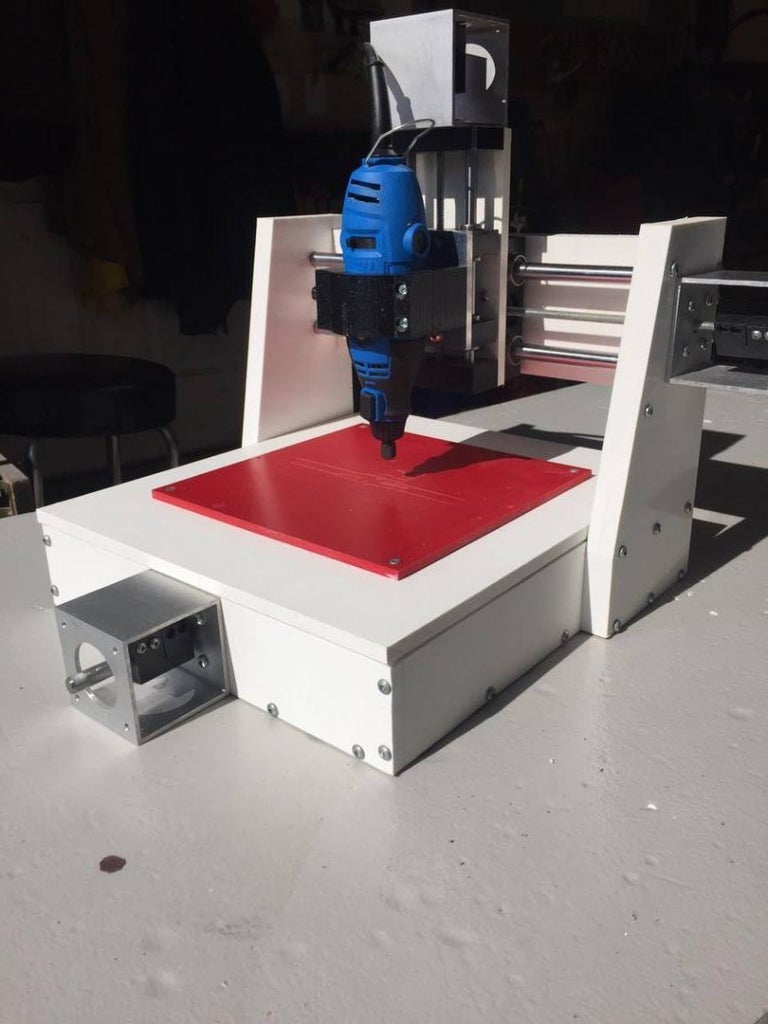

What is CNC Plastic Machining? In order to comprehend the breadth of experience Jaco has in CNC plastic machining, it is essential to also comprehend what "CNC" means. CNC represents computer system numerical control, and is a machining procedure in which a pre-programmed computer software application feeds directions to tools and equipment to produce items.

4 Simple Techniques For CNC Plastic Machining Services

CNC machines can manage grinders, lathes, mills, and more. Another benefit of CNC plastic machining is that it can enable three dimensional cutting tasks to be carried out in a single set of triggers. Because of that, it's chosen for more intricate parts. Manual machining needs that an operator exist to direct the device(s) utilizing levers and buttons.

This advanced approach just needs the ideal directions to feed to a machine, and it can finish jobs automatically. CNC Plastic Machining Types As pointed out, CNC maker for plastic productions can use a number of different tools and operations. Whether you require to finish PEEK CNC machining or a different type of CNC plastic process, here are some machines that might be utilized.

Utilizing CNC plastic machining, the lathes bring out the cutting with accuracy and high velocity. When compared to manual machines, CNC plastic operations can produce much more intricate designs that simply aren't possible without this advanced innovation. A plasma cutter works by utilizing a plasma torch to cut material. Rather than This Piece Covers It Well for plastic productions, the plasma cutter is most typically utilized in metal processing.

The smart Trick of CNC Plastic Turning Services - Brogan & Patrick Mfg.Corp. That Nobody is Discussing

The most standard CNC mills utilize a three-axis system (X, Y, Z) to shape parts. However, more advanced CNC plastic technology can often include up to three extra axes. Plastic CNC Machining Parts Although CNC machining can be utilized for a number of materials, Jaco Products specializes in dealing with a variety of plastics.